PKT Turbo has Partnered with Jiach Energy Solutions (JES) to Provide Turbo Drilling in India.

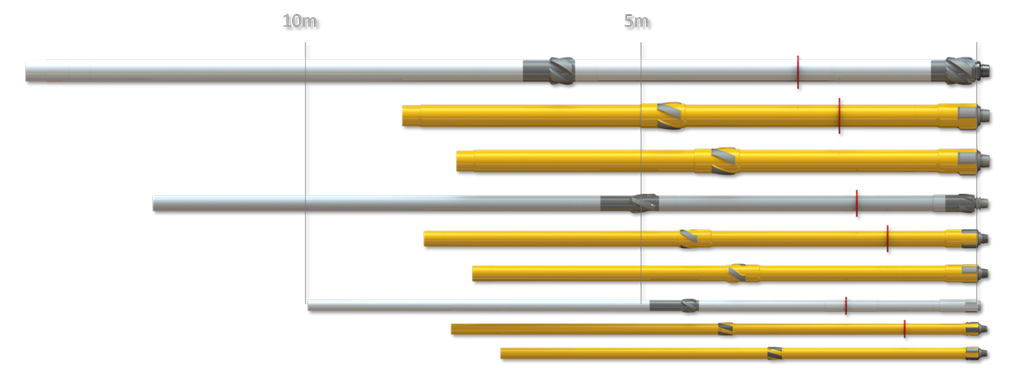

- PKT Turbo owns a completely new designed turbodrill which is known as the TurboDynamics series, and formed a unique effective technology for fast drilling for igneous rock, gravel layer, highly-abrasive quartz sandstone, in combination with uniquely-designed diamond-impregnated bits.

- In order to improve drilling efficiency, by extending the life of drilling tools, and to provide a quantum leap in overall drilling performance in certain targeted applications, PKT Turbo has established a service system for the whole drilling process from design to execution through the provision of a high technology turbo-drilling service..

- When applied in the correct application turbo-drilling can generally save drilling time by 40%-50% and overall drilling cost by 1/3. Hole quality is also often greatly improved which reduces the well bore tortuosity while drilling and can facilitate easier running of casing or production liner strings. Turbo-drilling is particularly well suited to deep wells, heavy mud weight scenarios, high down hole temperatures and formations that exhibit poor drill ability by conventional means. Taking into account different formations and well conditions, PKT Turbo can provide various combinations of diamond-impregnated bits and turbodrills of various configurations, which have been successfully used to drill directional wells, horizontal wells and high-deviated wells.

| Tool Size | Bit Size Range |

| 121 mm [ 4.3/4 in ] | 143-171 mm [ 5.5/8-6.3/4 in ] |

| 172 mm [ 6.3/4 in ] | 194-251 mm [ 7.5/8-9.7/8 in ] |

| 245 mm [ 9.5/8 in ] | 286-455 mm [ 11.1/4-17.1/2 in ] |

Compared with the conventional rotary drilling method,

- Turbodrills can double the average ROP, and greatly extend the number of meters drilled in a single run.

- By saving on the trip time, turbo-drilling has been proven to shorten the overall time to drill a hole section by 55% thereby lowering the overall drilling cost by 30%.

- Turbo-drilling technology has been proven to be a highly effective method to improve drilling performance in gravel layers, igneous rock and high abrasive quartz sandstones.

- Turbo-drilling technology is fully fit for the High temperature wells.

Examples of the advantages and efficiency improvement through turbo-drilling compared to conventional rotary drilling

| Lithology | ROP | Life of bit | Dull characteristics of bit | Advantages |

| Sandstone,mudstone(shale) | Increased by about 100% | About 20 times longer | Even and slight wear | Distinct ROP improvement, long life of bit, 50% time saved |

| Quartz sandstone | Increased by about 80% | About 8-10 times longer | Even wear | ROP and run length improved 50% time saved |

| Igneous rock | Increased by about 300% | About 20 times longer | Slight wear with long life | Distinct ROP improvement and long life of bit, 60% time saved |

| Gravel layer | Increased by about 30% | About 20-30 times longer | Slight wear with long life | Slight improvement of ROP, distinct improvement in run length, 65% time saved |