Jiach Energy Solutions has Partnered with Jet Lift System,Canada to provide Advance Jet Pump Technology for India Market.

Down Hole Configuration

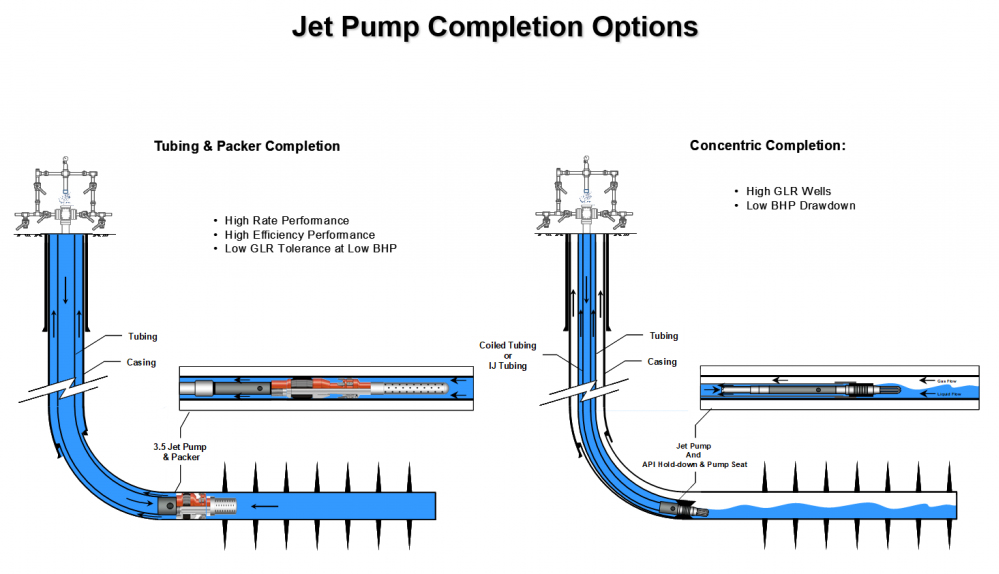

Concentric Tubing – the Jet Pump is run on the bottom of a coiled tubing string inside the production tubing. The Jet Pump seats into a profile, (typically a PSN – pump seat nipple) to a seal between the power fluid and the formation fluids. Power fluid is pumped down the coil tubing, a venturi effect is created in the jet pump drawing the formation fluid into the jet pump. The power fluid and formation fluid discharges out the side of the jet pump and is circulated to surface up the coil tubing annulus. Solution gas flows up the tubing-casing annulus. This configuration is recommended in low to medium volume wells with higher GOR.

Tubing and Packer – the Jet Pump is run in on end of the tubing string with a packer landed immediately below it. The packer is set to isolate the circulating power fluid from the formation fluid. The power fluid is pumped down the tubing, a venturi effect is created in the jet pump drawing the formation fluid into the jet pump. The power fluid and formation fluid discharges out the side of the jet pump and is circulated to surface up the casing tubing annulus. This configuration is recommended in high volume wells with lower GOR.

- DH Sensors with jet lift equipment

- Packer for Jet Lift pumps

- Associated PCP Surface pump

- Variable Frequency Drive

- Associated HPS Pumps

- Associated Well head with Manifold

- Intake Strainer / Separator

- Power fluid Tank

- Free water knockout tank

- Well head equipment